Monolith

澳洲幸运10开奖历史号码结果

Spend less time running expensive, repetitive tests and more time learning from your engineering data to predict the exact tests to run.

Our AI Software

No-code AI software built for engineers

Monolith is a machine learning AI platform built by engineers, for engineers. No coding or Ph.D. in statistics is required - just your engineering expertise and test data.

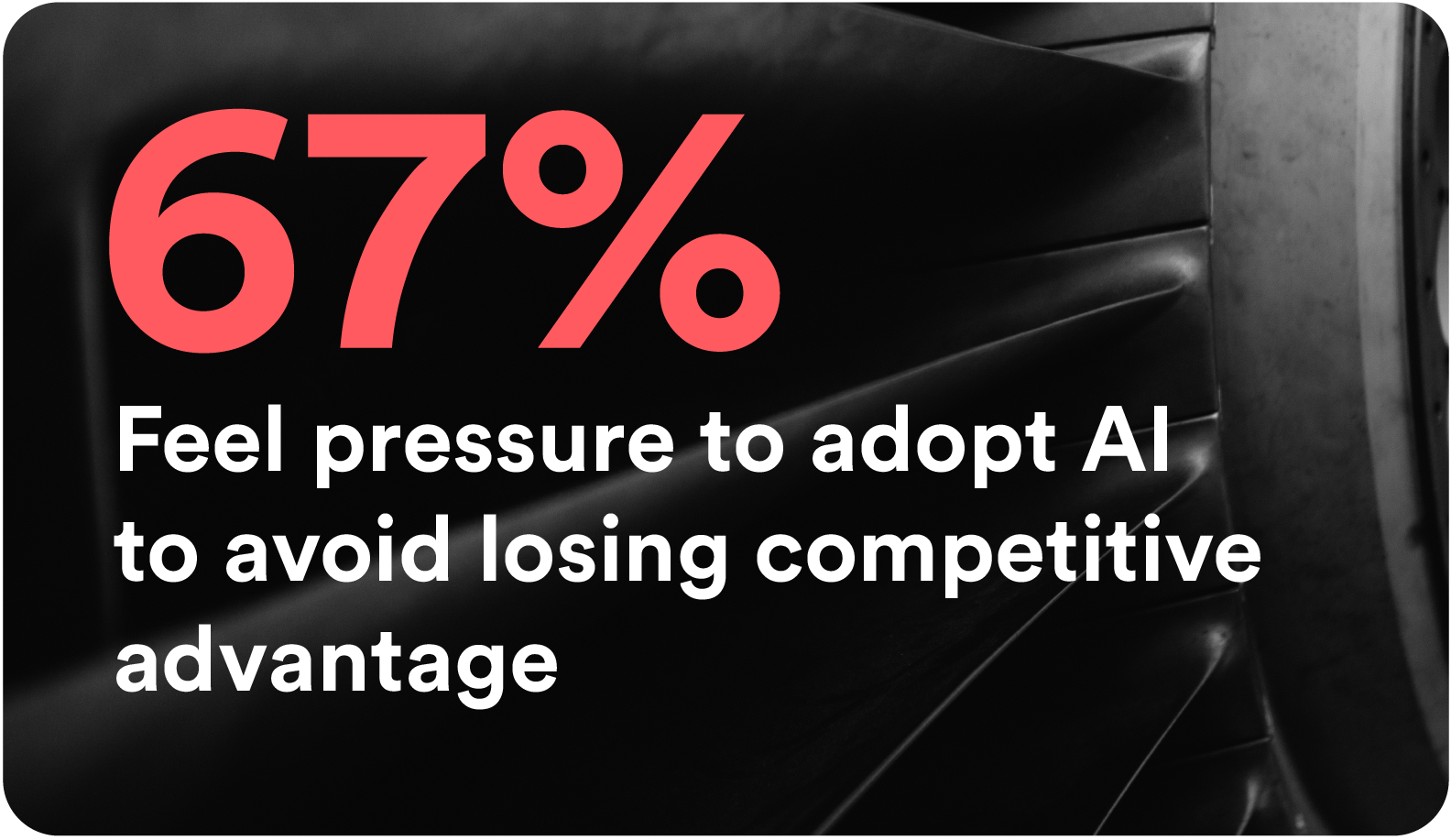

A commissioned study conducted by Forrester Consulting on behalf of Monolith

The State of AI in Engineering

The first-ever study on AI in product development surveys US and European automotive, aerospace, and industrial engineering leaders.

Trusted by top engineering teams to cut product development time.

The world's top engineering teams use Monolith to develop better quality products faster with machine learning models.

Request a Demo

Build accurate self-learning models.

Use your engineering data to create accurate self-learning models to quickly understand and instantly predict the performance of complex physics & explore more operating conditions through our machine-learning platform.

Named by Gartner as a Cool Vendor in AI for automotive.

“Companies such as Monolith…apply their AI Software to improve vehicle development, quality control, and inspection, ensuring lower costs and higher levels of safety and quality.”

Discover our top data-driven business applications and engineering use cases for Aerospace & Defense, Automotive, and Industrial customers.

Monolith's AI afotware supports a diverse range of industries, engineering teams, and business requirements. If you work with any type of data; from data science, to data entry, data preparation, data management, or make data-led decisions—our AI software can help you do more with less.

Vehicle Dynamics

Use Monolith’s intelligent exploration artificial intelligence tools to sort and visualise track test data, inform your engineers, and train machine learning models on manoeuvres to predict the forces on the vehicle during other manoeuvres that were not performed—saving testing time on complex tasks.

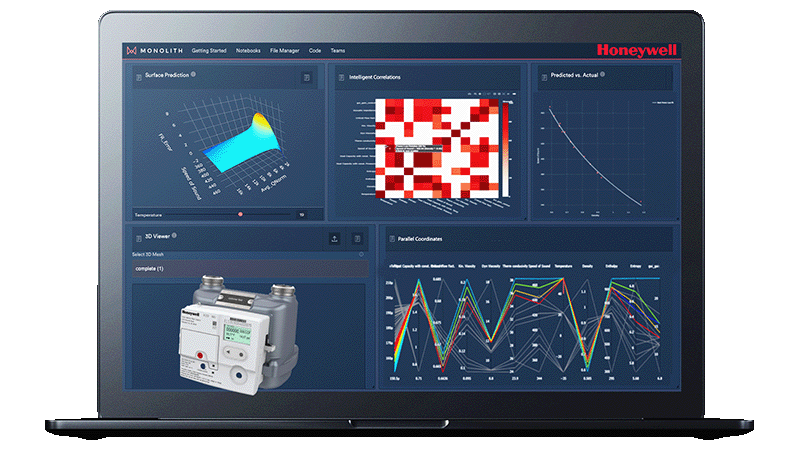

Smart Meters

Monolith's AI software instantly determines what smart meter designs give the best performance, while self-learning models learn from new data generated along the way, indicating which designs are most promising to investigate next through machine learning.

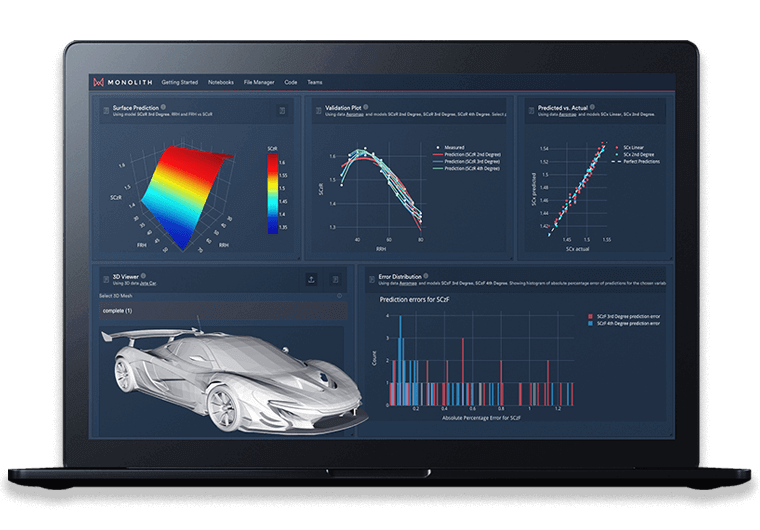

Wind Tunnel Testing

Build 3D artificial intelligence (AI) models that directly predict wind tunnel performance from a CAD design – faster and more accurately than Computational Fluid Dynamics (CFD) simulation alone.

今日澳洲官网app下载安装

Automotive

Named a Gartner Cool Vendor for AI in Automotive, Monolith is trusted by the world’s top engineering teams to build self-learning models that empower your engineers to do less testing, more learning, and develop better quality products in half the time with artificial intelligence software and pre-trained models.

Industrial

Monolith's artificial intelligence software empowers engineering domain experts in industrial markets to reduce expensive, time-intensive testing, lower risks to product performance and quality, and cut product development time—ultimately speeding up business processes and time-to-market.

Aerospace & Defense

Monolith founder Dr. Richard Ahlfeld received his PhD in Aerospace Engineering from Imperial College and was named in MIT Technology Review’s Top 10 Innovators under 35. With a keen focus, Monolith strives to save time for and support aerospace engineers in solving their most intractable physics problems through our state-of-the-art artificial intelligence software.

Kautex-Textron webinar

Use AI to predict fuel-sloshing noise, solve intractable physics

- Problem: Vehicle acoustics

- Methods tried: CFD, physics-based simulation

- Solution: Predict noise, reduce testing with self-learning models

“Monolith allowed us to understand and optimize the gas meter's behaviour for all operating conditions and optimize meter accuracy under extreme conditions, allowing us to build a superior, more accurate product in a much shorter amount of time.”

- Bas Kastelein, Sr. Director Product Innovation, Honeywell Process Solutions

“Monolith Team understood what it means to work with genuine engineering problems in artificial intelligence: the needed flexibility and knowledge. ”

- Joachim GUILIE, Curing performance expert at Michelin

“The Monolith engineering team are unique experts in the field of solving scientific problems with machine learning. I trust them to guide our team to get the greatest ROI from AI and magnify our engineering talent and expertise. ”

- Dr. Paul Gosling, Chief Technology Officer, Thales UK

“With Monolith’s machine learning method, we not only solved the challenge, we also reduced design iteration times and prototyping and testing costs. We are thrilled with the results, and we are confident we have found a way to improve future design solutions.”

- "Dr. Bernhardt Lüddecke, Director Validation Global Kautex-Textron

Four ways to use AI to cut validation costs

Build shorter test plans, create fewer prototypes, find errors faster, and validate designs more quickly using AI-based self-learning models.

1. Automatically detect faulty sensors

To avoid downstream issues, your engineers must tediously inspect test data for errors. One failed sensor or wiring malfunction can render thousands of dollars in testing useless.

- Prepare your data for optimal AI performance

- Catch bad data now so you avoid re-engineering later

- Find outliers in your test data fast with intuitive visualisation

2. Predict the critical tests to run

Test too much and you waste time confirming what you already know. Test too little and risk missing performance issues. Schedule, quality and your career depend on finding the balance.

- Run the most important tests and skip the rest

- Optimize resources spent on costly test rigs and facilities

- Validate your designs faster with fewer prototype iterations

3. Determine the cause of system failure

Product design issues during validation risk launch delays and lost market share. Pressure on engineers is high to identify critical parameters causing failure, quickly analyze the root cause, and predict how the product will perform in changing conditions.

- Predict what design changes will most likely fix the failure

- Identify components causing sub-optimal performance

- Avoid long delays and uncertainty in the validation process

4. Calibrate for thousands of conditions

Designing highly complex, non-linear systems that must meet stringent performance standards is challenging. Predicting which combination of inputs will deliver the optimal output, in all operating conditions, is next to impossible.

- Calibrate complex dynamic systems

- Ensure your system performs to spec in all conditions

- Find best-fit values across 1000's of inputs and conditions

Get Started

Get started with Monolith, your trusted AI partner

Learn how to begin AI adoption in your engineering organization and understand the technical requirements for the applicability of artificial intelligence software to your organization.

Find out how we support the world's top engineering teams, and how you can be sure you will succeed with AI to deliver better quality products in half the time.

New Feature

Next Test Recommender (NTR): AI-powered test plan optimisation

Learn how our AI software's latest feature enables users to train and assess machine learning models. It offers valuable recommendations for optimal test conditions to apply in the next round of testing. NTR assesses previously gathered data to suggest the most effective new tests to conduct.

Case Study

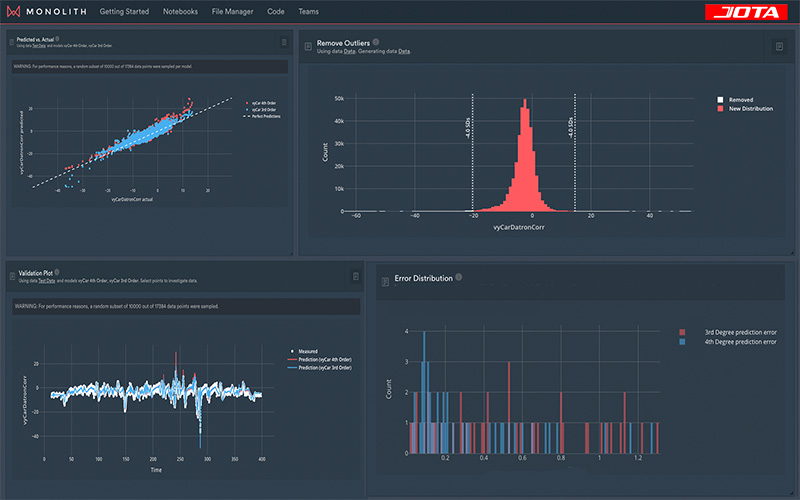

JOTA cuts car setup time by 50% with AI

Since teaming up with Monolith, JOTA engineers can better understand and predict the aerodynamics of their cars by building AI self-learning models. As a result, they reduced the number of simulations and tests by 50%, cut car time-to-setup in half, and achieved a 66% reduction in overall costs.

_4_w_66165a.png)